Letterpress printing is truly the most beautiful craftsmanship - It is a century old art form, which is timeless, classic and results in a beautiful tactile impression into the paper.

Letterpress Printing is the oldest and one of the most exquisite forms of printing available. Letterpress hasn't changed much since 1440 when Gutenberg developed movable type and the first ever printing press was invented. For the last 520 odd years, letterpress was the most common form of printing, it was a craft of masters, it was something terribly precious. However, during the last century, the development of faster, motorised offset printing presses meant that centuries of knowledge and craftsmanship were lost in an instant.

Letterpress

Studio Nine

Letterpress Products

1959 Heidelberg Platen

Herbie is just a baby in Letterpress terms as he was built in 1959.

Weighing in 1200 kilos, he is a monster of the beautiful old machine. Heidelberg T Platens are german engineered and are otherwise known

as Windmills - This is due to the two arms which rotate around the press just as a windmill does.

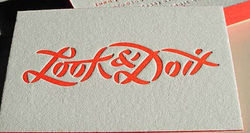

Business Cards

We are pleased to now offer letterpress business cards, printed the beautiful old fashioned way, using antique cast iron letterpresses, the finest papers, and exceptional craftsman print quality.

100% cotton: Made from 100% recycled cotton Available in White or Ivory in 300 or 450gsm.

Wild: Made from 35% recycled cotton, Available in Off-white 450gsm.

Wedding Invitations

Letterpress wedding invitations are simply the most beautiful introduction to a wedding.

We print the old fashioned way, using antique cast iron letterpresses and print on

luxuriously thick 100% cotton paper, which we couple with classic and beautifully crafted designs.

Tags |  Oil base Letterpress Ink |  Wedding Invitation |

|---|---|---|

Etching Plates |  Gift Tag |  Invitation Cards |

Tags |  Letterpress |  Ticket |

1959 Letterpress Platen |  Business Cards 300gsm Cotton |  Letterpress Tools |

Business Card Etching Color |  Business card zinc plate |  Letterpress Color Etching |

Letterpress Tags |  Letterpress Set up |  Type |

What is Letterpress Printing?

The working of the printing process depends on the type of press used, as well as any of its associated technologies (which varied by time period).

Hand presses generally required two people to operate them: one to ink the type, the other to work the press. Later mechanized jobbing presses

require a single operator to feed and remove the paper, as the inking and pressing are done automatically.

The completed sheets are then taken to dry and for finishing, depending on the variety of printed matter is produced. With newspapers, they are taken to a

folding machine. Sheets for books are sent for bookbinding. You can distinguish a traditional letterpress printer from a digital printer by its debossed lettering. A traditional letterpress printer made a heavy impression into the stock and producing any indentation at all into the paper would have resulted in the print run being rejected. Part of the skill of operating a traditional letterpress printer was to get the machine pressures just right so that the

type just kissed the paper transferring the minimum amount of ink to create the crispest print with no indentation. This was very important as when the

print exited the machine and was stacked having too much wet ink and an indentation would have increased the risk of set-off (ink passing from the front

of one sheet onto the back of the next sheet on the stack) - Wikipedia -